Hocklynn is a specialist stainless steel fabrication company based in Bristol, delivering bespoke components and assemblies to OEMs and equipment manufacturers across the UK. We produce complete products, not just laser cut flat parts. Every job moves through our full in-house capability: profiling, CNC forming, joining and surface finishing.

Our fabrication services cover individual prototypes through to repeat production runs. Most of our clients need short-run manufacturing, typically 5 to 10 units per batch, with the option to scale as demand grows. Once tooling is set up and CNC programs are stored, subsequent orders run faster and with consistent quality throughout.

We are not a commodity profiling shop. We make complete fabricated assemblies, enclosures and precision components. The engineering input we provide during setup is what makes repeat orders efficient and keeps our clients coming back.

Choosing the right grade matters. We fabricate primarily in 304 and 316 stainless steel, the two most widely specified austenitic grades for industrial applications.

304 offers excellent corrosion resistance and formability. It suits most enclosures, brackets, panels and fabricated assemblies in dry or mildly corrosive environments. 316 contains molybdenum, giving it superior resistance to chlorides and harsher conditions. We recommend 316 for outdoor housings, coastal installations and applications where long-term durability is critical.

We also handle other grades on request and can advise on which material best balances performance against cost for your specific application. Getting the grade right at the start avoids costly rework later and ensures the finished component performs as intended throughout its service life.

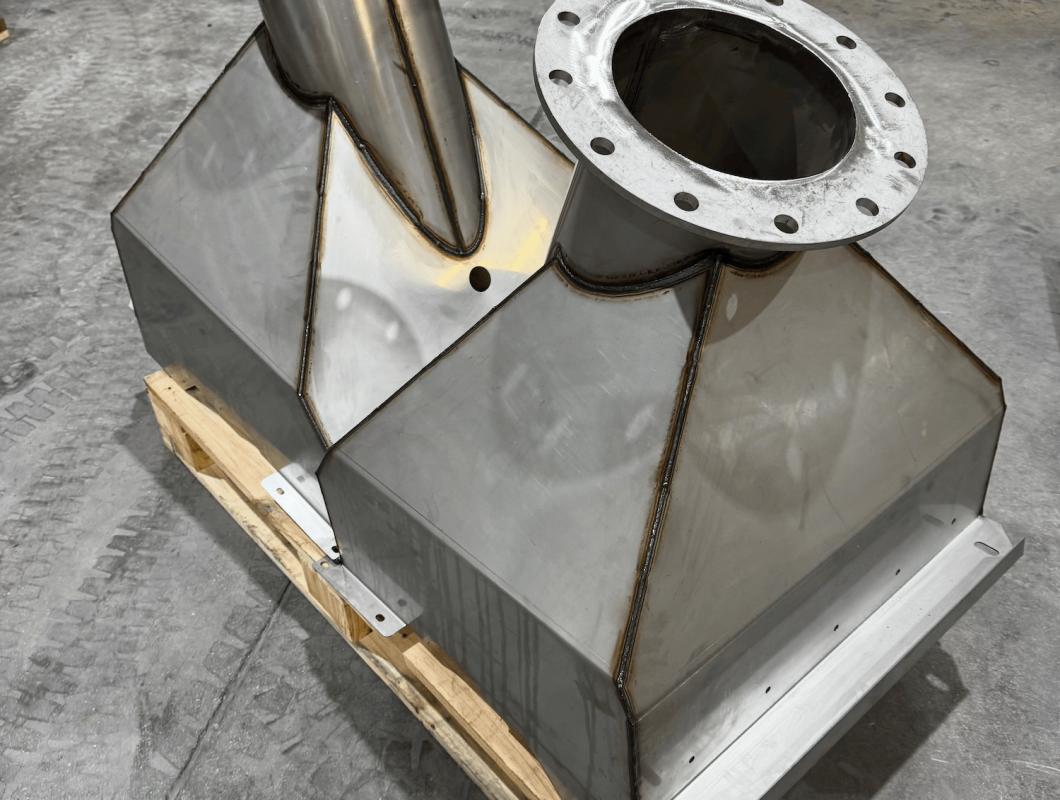

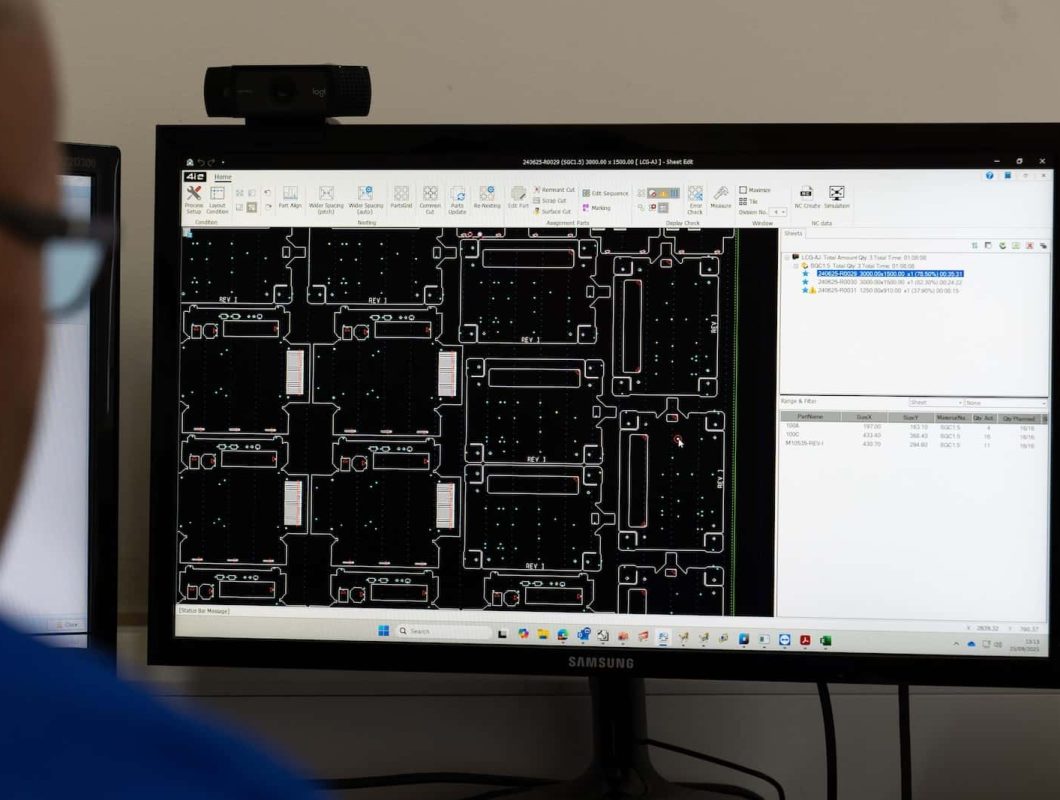

We work with your drawings or CAD files and run components through our CNC fibre laser for cutting, our CNC LVD 8-axis press brakes for forming, and on to our skilled team for assembly and finishing. This complete stainless steel sheet metal fabrication process runs entirely in-house, meaning fewer handoffs, tighter quality control and faster lead times than splitting the job across multiple suppliers. If we spot anything that could cause problems during production, we raise it early.

We programme everything from your CAD data, so accuracy is maintained from the first piece to the last. If you supply 2D drawings rather than 3D models, our in-house CAD team can generate the files needed to drive our CNC equipment.

Stainless behaves differently to mild steel. It work-hardens during forming, has higher springback, and demands careful handling during welding to preserve its corrosion-resistant properties. Our fabricators have decades of hands-on knowledge with these characteristics and compensate at every stage of the process.

After joining, we use electrolytic weld cleaning to passivate joints. This restores the protective surface layer without the environmental and safety issues of acid pickling pastes. The result is a clean, consistent finish that performs reliably in service.

The right finish transforms a functional component into a product that looks as good as it performs. We offer brushed, grained, dull-polish and silicone finishes matched to your visual and functional requirements.

For visible or customer-facing stainless steel components, finish quality is not optional. Our team knows how to handle stainless without contamination or marking. Talk to us about your finish requirements at the quoting stage so we can factor them into pricing and lead times.

We manufacture bespoke stainless steel enclosures for a wide range of industrial applications. Electrical enclosures, control cabinets, outdoor housings, protective covers and CCTV housings are all regular output from our workshop.

Each enclosure is built to your exact specification: profiled panels, formed sides and doors, welded construction, fitted hardware and finished surfaces. We handle the full build in-house, which gives you a single point of contact and accountability from order to delivery.

If you are developing a new enclosure product or need a reliable supplier for ongoing batches, we can support you from initial prototype through to steady repeat manufacturing. Our setup and programming is retained between orders, so repeat runs are straightforward and cost-effective.

Hocklynn supplies stainless steel fabricated components and assemblies to OEM manufacturers and industrial builders across the UK. Conveyor system manufacturers, security companies, power and control system integrators, and commercial vehicle outfitters all rely on us for consistent, high-quality output.

We are set up for the kind of production these industries demand: complex multi-component assemblies, tight tolerances, repeatable quality batch after batch, and the engineering input to suggest improvements that reduce cost without compromising function. This is not commodity sheet metal. We add value through our fabrication expertise and build lasting partnerships with businesses that need a dependable supplier.

Repeatability matters. When you order the same stainless steel component month after month, you need it to arrive looking and performing identically every time. Our CNC-driven processes, stored programs and documented setups ensure that batch number fifty matches batch number two.

We inspect to your specification. Our MIE Trak ERP system provides full traceability from material receipt through to final inspection. If your end application demands a specific standard or documentation package, talk to us at the quoting stage and we will confirm what we can provide.

Many stainless steel fabrication jobs start with a single prototype. We help our clients prove out their designs before committing to batch quantities. Prototypes are made using the same methods and materials as final production runs, so there are no surprises when you scale up.

Once the design is signed off, the transition is straightforward. We retain all CNC programs, tooling setups and quality records. Your second order and every one after runs faster and with lower cost per unit than the first.

This prototype-to-production approach is a key reason OEMs choose to consolidate their stainless steel fabrication with us. A single supplier, a single relationship, a consistent standard of quality from first article through to repeat delivery.

If a component could be made better or cheaper, we will tell you. Our design for manufacture input helps reduce fabrication cost, simplify assembly and improve consistency without changing function or performance.

Small changes to bend radii, hole positions, gauge or joint design can make a significant difference to production time and scrap rates. We review every new job with fresh eyes and flag opportunities to improve manufacturability before production begins. That consultative approach is a core part of our service and a reason many of our OEM relationships last for years.

Our workshop is based in Eastpark Trading Estate, Bristol, BS5 7DR. While many of our clients are in Bristol and the South West, we deliver fabricated stainless steel components to businesses across the UK.

We have been producing stainless steel fabrication in Bristol for over 50 years. That depth of knowledge shows in the quality of our output, the reliability of our delivery dates and the long-standing relationships we hold with clients across multiple industries.

It is the process of transforming stainless steel sheet into finished components and assemblies through a combination of profiling, forming, joining and finishing. At Hocklynn, we provide a complete service from raw material to inspected, ready-to-use products.

The most common grades are 304 and 316. Grade 304 is the general-purpose choice offering good corrosion resistance and excellent formability. Grade 316 adds molybdenum for improved performance in harsher environments. We can advise on which grade suits your application.

Both are readily weldable using TIG and MIG processes. 304 is slightly easier to handle due to its lower alloy content. 316 needs a bit more care to maintain corrosion resistance in the heat-affected zone, but with experienced operators and proper post-weld cleaning, both produce strong, reliable joints.

Lead times depend on complexity, quantity and current loading. Simple profiled and formed components can often ship within a few days. Welded assemblies and enclosure builds typically take one to three weeks. We provide accurate timescales at the quoting stage and keep you updated throughout.

Need a quote, technical advice or lead time confirmation? Send us your drawings or specifications and our engineering team will get back to you with clear answers.

Call 0117 951 7572 or email sales@hocklynn.co.uk