Whether you’re starting from a rough concept or providing detailed drawings, we use SolidWorks 3D modelling to ensure every component is engineered for accuracy, strength, and manufacturability. Our CAD process integrates seamlessly with our CNC equipment, reducing setup times and eliminating translation errors.

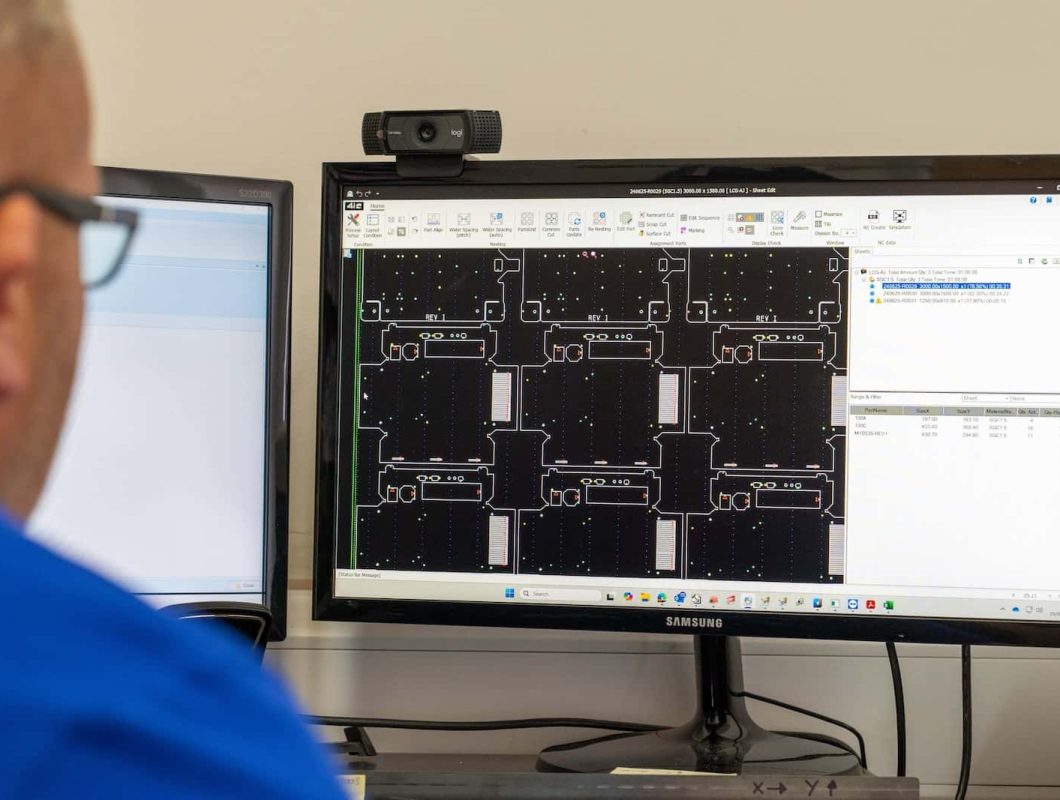

We use SolidWorks to create precise designs for efficient downstream processing. Our engineers can develop designs from scratch or refine customer drawings provided as a sketch or in DXF, DWG, and STEP files for improved manufacturability. Every file we produce is optimised for clean data flow into our laser cutting and press brake systems.

Our team works closely with your designers to identify opportunities for cost savings and improved performance. We regularly host customer design sessions, providing insight into sheet metal manufacturing constraints and possibilities — helping your team design smarter, faster, and more efficiently.